No Products in the Cart

The Asphalt Superpave test is a method used to evaluate the performance characteristics of hot-mix asphalt. It is used by pavement engineers to select mixtures that will perform well under specific traffic and weather conditions. The result is the selection of durable, long-lasting mixtures which ultimately reduces the cost of maintaining and repairing roads.

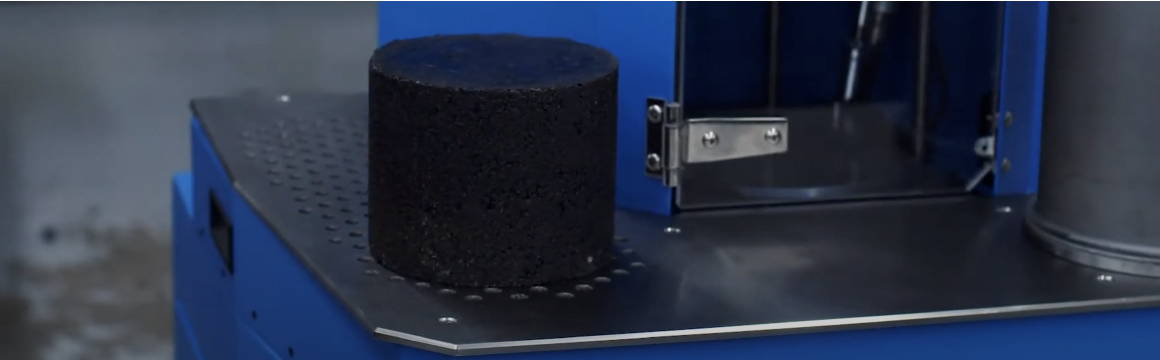

The Superpave gyratory compactor (SGC) uses a hydraulically powered kneading system which simulates the field densification of the mix. The applied force is constant, the number of gyrations can be controlled, and the device produces feedback on the compactability of the asphalt material. Before performing the test, it is important to make sure to wear heat resistant gloves when touching any metal parts including after the compaction and demolding.

1. Sampling:

The asphalt mixture should be sampled in accordance with ASTM D75 or AASHTO T168. The samples should be placed in cylindrical molds, with a height of 50 mm (2 inches) and a diameter of 102 mm (4 inches).

2. Compaction:

- The samples should be compacted using a gyratory compactor, such as the Superpave, in accordance with ASTM D6925 or AASHTO T312.

- The compaction should be performed at a temperature of 163°C (325°F) and at a specific number of gyrations, depending on the type of asphalt mixture.

- The samples should be removed from the molds after compaction and stored in a moisture-controlled environment prior to testing.

3. Testing:

- The samples should be tested in accordance with ASTM D7175 or AASHTO T324, which measures the dynamic modulus and flow number of the asphalt mixture.

- The test should be performed at a frequency of 1 Hz and at various temperatures, typically between -10°C and 40°C (14°F and 104°F).

- The dynamic modulus, which is a measure of the asphalt mixture's stiffness, is calculated from the test results.

- The flow number, which is a measure of the asphalt mixture's rutting potential, is also calculated from the test results.

4. Analysis:

- The test results should be analyzed to determine the performance characteristics of the asphalt mixture, such as its stiffness, rutting potential, and fatigue resistance.

- The results should be compared to the Superpave performance criteria to evaluate if the mixture is suitable for the intended use.

- The results can also be used to adjust the asphalt mixture design or to select the most appropriate asphalt binder for the mixture.

It is important to note that The Superpave test is a laboratory test, and it is required to follow the ASTM/AASHTO standards in order to ensure the accuracy and comparability of test results. It is also required to have properly calibrated equipment, trained technicians and a controlled environment during the testing process.

Additionally, standards may be updated or revised over time, so it is always a good idea to check for the latest versions of the standards and to consult with a qualified professional if you have any questions.

For more detailed information about the Superpave test, please refer to the following source: